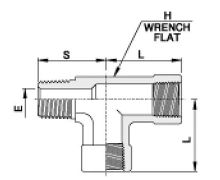

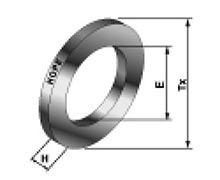

Hy-Lok USA, Inc. precision pipe fittings are designed for instrumentation and process control.

Hy-Lok pipe fittings are available in a wide assortment of thread combinations and sizes for easy transition from one thread design to another, or to accommodate increases and reductions in pipe fitting thread sizes.

Hy-Lok Pipe Fitting Features:

- Many different connections and configurations.

- Standard materials are S316, brass and carbon steel.

- Size ranges from 1/8″ thru 2″ NPT.

- Precision thread construction to ensure leak-free and reliable systems.

- Working pressure calculated in accordance with power piping code ANSI B31.1 and refinery piping code ANSI B31.3

These fittings are manufactured by Hy-Lok using tapered threads that are of the highest quality. They are constructed in a variety of configurations, so they are capable of use in a broad variety of applications. They have pressure ratings that are suitable for temperatures as high as 100°F, as the product listings show.

The basic fitting capabilities show the fittings will stand up during prolonged exposure to temperatures as high as 800°F. Those ratings are dependent upon the design and whether the fitting is 316 stainless steel or brass. Fittings made of 316 stainless steel are heat code traceable for the benefit of your operation.

The sizing and part numbering for these Hy-Lok pipe fittings are easy to understand and also descriptive in nature. These high-quality fittings are easily connected to be tight enough to avoid leakage if a pipe thread sealant is used.

Pipe Fitting Materials

While the standard materials are 316 stainless steel, brass and carbon steel, we can also manufacture these fittings in other materials to meet your company’s needs. Other optional materials include Hastelloy C, Inconel, Monel and titanium. We can also fill custom orders so the shapes and specifications can be done per your specific needs.

Safety Precautions:

When you use Hy-Lok fittings, be sure to follow all of the safety procedures. Do not attempt to loosen the fitting or any other part, such as a valve, when the system is pressurized. Before you attempt to loosen or tighten any connection, make sure the system is not pressurized. Make sure the specifications for pressure-temperature are followed precisely. If a hazardous or toxic liquid is involved in the application, exercise due caution during any maintenance or operation procedures.

Any tubing that is used must be compatible with the valve or fitting material. Make sure straight tubing is found between the fitting and the tube bend because a tube that is bent or crooked near the connection for the fitting could result in leakage.

HAVE A QUESTION?

If you have any questions about any of our products or services, don’t hesitate to give us a call. For any inquiries, fill out the form and one of our Hy-Lok representative will contact you soon.